Semiconductor Digest Editor Shannon Davis shares the news of Omnitron Sensors‘ manufacturing collaboration with Silex Microsystems–the world’s top MEMS foundry.

Semiconductor Digest Editor Shannon Davis shares the news of Omnitron Sensors‘ manufacturing collaboration with Silex Microsystems–the world’s top MEMS foundry.

When Thomas A. Edison invented the phonograph in 1877, he first envisioned its use for letter writing and other forms of dictation, but he didn’t foresee that his invention would one day transform the way that people listen to music, expanding that experience from live performance only to recorded music in the comfort of one’s own home.

Let’s go one step further. Read this excerpt from the December 22, 1877 issue of Scientific American with a modern eye, and you might think that Edison’s work portended the invention of AI-enabled chatbots that mimic human conversation: “Mr. Thomas A. Edison recently came into this office, placed a little machine on our desk, turned a crank, and the machine inquired as to our health, asked how we liked the phonograph, informed us that it was very well, and bid us a cordial good night.”

On a literal level, we can’t draw a linear connection, but on a conceptual level, Edison was onto something. His work—as well as that of other pioneers who followed him closely, including Alexander Graham Bell—laid the foundation for future voice and acoustic applications, including smart speakers, cellular phones, and digital audio books.

Innovation in MEMS has progressed similarly. It has not always moved in a linear fashion, but there have been flashes of brilliance along the way. The first MEMS accelerometers in air bag crash sensors, commercialized by Analog Devices in the mid- to late 1990s, proved that MEMS devices can be manufactured in high volume and used in environments with high vibration and wide temperature variation. The Nasiri-Fabrication platform, which InvenSense used to manufacture the first high-volume MEMS gyros for consumer applications in the early 2000s, was another major leap in innovation.

Here we are in 2023, with billions of MEMS sensors now deployed in thousands of different electronic applications, and innovation has stagnated. Our industry still contends with the limitations of non-standard processes and packaging approaches, long design-to-delivery life cycles, varying degrees of high cost, and issues with reliability and accuracy. Despite this, MEMS technology has unlimited upside potential. All we need to do is fix it at a foundational level.

That’s what we’re doing at Omnitron Sensors. We’re disrupting the market with a new topology for MEMS that simplifies fabrication to improve capacitance, increase ruggedness, improve yield, speed design-to-manufacture, and reduce cost. And it’s through our new topology for MEMS that we’re able to build better MEMS devices that span markets and applications, from the first MEMS step-scanning mirrors for LiDAR to better IMUs, better actuators, and better pumps.

Interested in learning more?

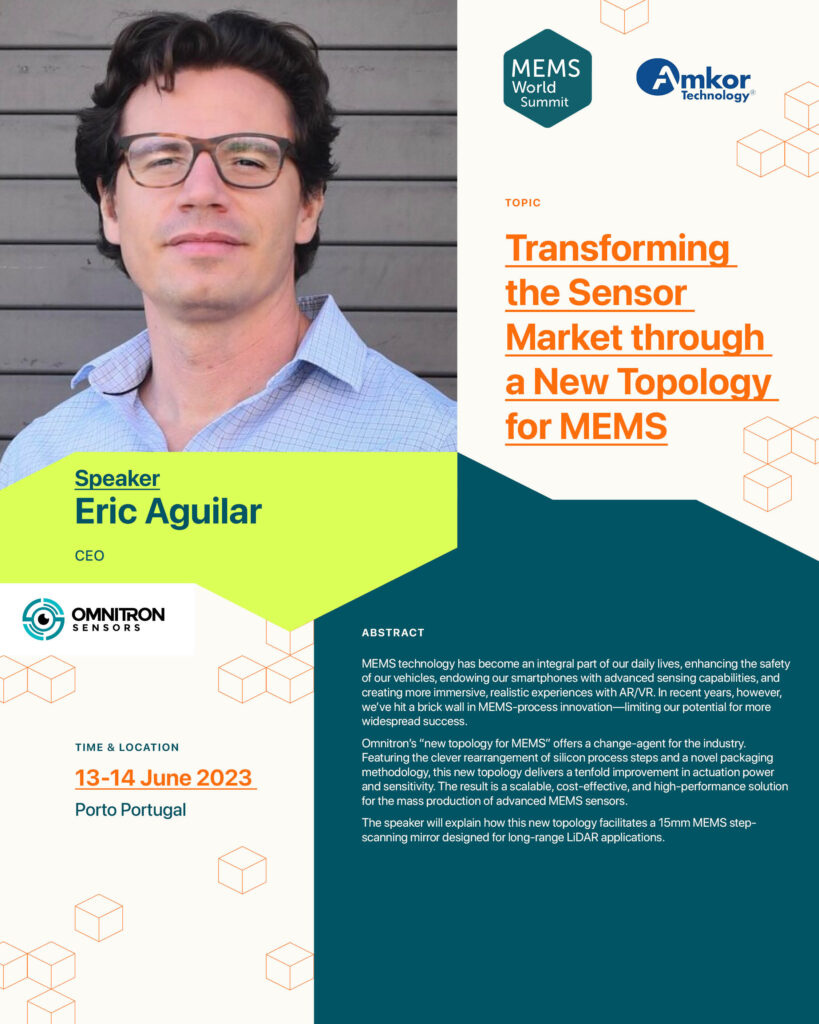

Omnitron Co-founder & CEO Eric Aguilar will present Omnitron’s new topology for MEMS at MEMS World Summit Europe, June 13-14, 2023 in Porto, Portugal. There’s still time to register for this annual event, which attracts industry leaders and decision-makers from the global MEMS and sensors industry.

Or, if you’re not able to attend MEMS World Summit Europe, please email Omnitron Sensors today.

“Omnitron Sensors is a new kind of semiconductor process development company. In the semiconductor industry, innovation is always tied to the newest technology node. In MEMS, it’s all about topology.”

Omnitron is on a mission to shake up the MEMS market, breaking through existing barriers in MEMS manufacturing today to facilitate the creation of the high-performance, low-cost sensors that will be ubiquitous in the world of tomorrow. The leadership team’s broad range of experience across some of the world’s leading companies means not only do they have the technical skills needed to make this vision a reality, but also that they have a huge network spanning the globe that will be vital to their success as they grow.